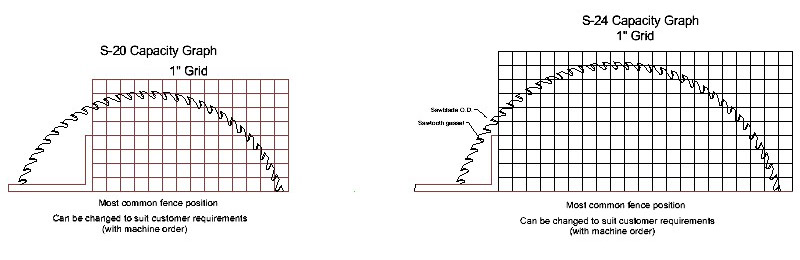

The Model S-20 machine

was developed to satisfy the requests from existing customers operating

our model M-20 machines, but needed additional cutting production

without the mitering capability. Both our customers & we knew of other

up-cut saw manufacturers, and quite frankly, we tried to sell them

on these other machines. After all, why try to reinvent the wheel?

Our customers informed

us that they liked the features & quality of our model M-20 machines,

so they wanted us to build them a straight up-cut saw. The results

are our S-20 & S-24 model machines.

Operation:

Operator pushes either

left or right button located on front door control box. This brings

the clamp/guard assembly down onto work piece. While holding this

button, operator pushes second button. This cycles the blade up &

down to make the cut. This method of operation ensures the operator

cannot have a hand or finger in the cutting area of the machine. Releasing

either button at any time lowers the blade below the table.

Standard Features:·

- Machined flat table

top - ensures precise square cuts - makes auto-feeding of materials

easy

- 4" high fence rail

clear through machine - helps in supporting & feeding of multiple

pieces

- 20" (S-20) or

24" (S-24) x 100 tooth, TCG, Carbide Tipped Saw Blade

- 10 HP, tefc, 3 phase

motor

- Magnetic starter with

solid state overload relay

- 24 vdc machine controls

through plc

- 2 Hand cycle control

- Saw access door kill

switch

- "Quick Adjust Rod" for

proper clamp/guard height

- Easy to reach saw cut

speed control

- Saw access door switch

- Motor brake (S-24)

- Air filter/regulator

with shutoff valve for air supply

- OSHA safety blow gun

Optional Equipment:

- Solid or roller in-feed

& out-feed tables

- Manual & Air operated

6 " high x 9" long swing up material stops

- NC or full CNC controlled

auto feed systems

- Air Over Oil control

of saw cutting speed (for nonferrous metals)

- Saw blade lubricator

for cutting nonferrous & some plastics

- Laser light (shows blade

position on top surface of work piece with clamp/guard raised)

- Clamp/guard height extension

to allow oversized material to be processed

- Speed sensing of sawblade

to prevent overloading motor when cutting oversized materials.

- Horizontal Clamps

- Tilt Frame

- Safety hood enclosure

for Auto-Cycled machines

Vista Machines is an OEM

systems integrator for TigerStop automated material stops. We can

supply a complete cutting system to customer requirements or work

with machine distributors to ensure a trouble free turnkey system

for their customers.